Sanitary Fittings

Shop Now »

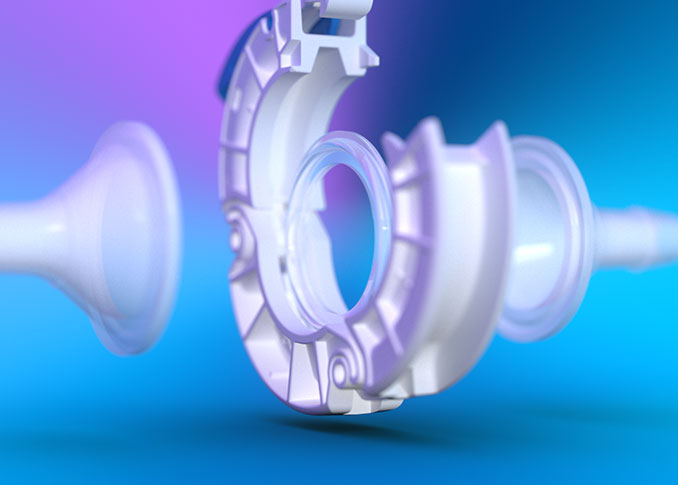

Plastic Flange Fittings

Reliable Fluid Transfer

SF Series sanitary fittings are designed for single-use container fluid transport systems, manifolds, and wherever sensitive fluids must be transferred. They are offered in four flange sizes, 3/4" ("Mini"), 1-1/2", 2", and 3" ("Maxi"). All work with flanges made to ASME-BPE specifications. SF Series sanitary fittings incorporate 600 Series barbs for easy use with silicone, C-Flex® or Tygon® tubing.

Connectors of Choice

For Single-Use Bioprocesses

The SF Series is based on design concepts calling for a heavy-duty part with superior side load strength, while also providing superior flow through characteristics, making them the connectors of choice for single-use bioprocesses. Pharmaceutical professionals find these plastic fittings offer all the benefits of disposable parts while offering performance capabilities not found in earlier versions of flanged fittings.

Interconnectibility

Seamless Integration

Nordson MEDICAL's sanitary fittings and high-efficiency caps have been tested to seamlessly connect with a wide range of commonly available plastic and traditional stainless steel parts. This capability ensures versatile integration and operational flexibility across diverse setups and applications, promoting ease of assembly and consistent performance.

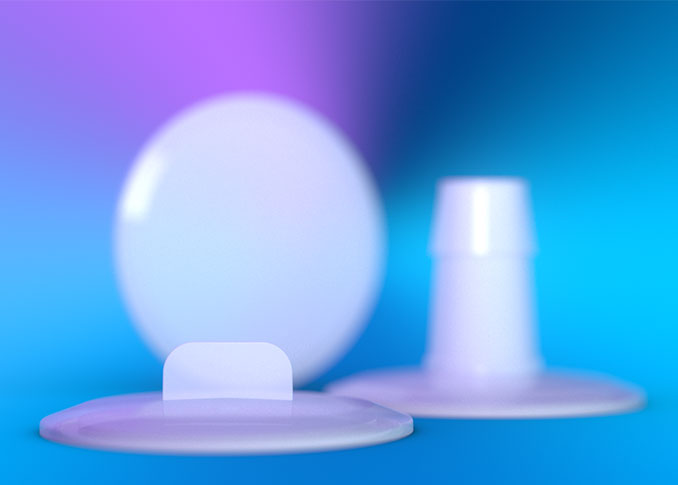

Expanded Line of Sanitary Fittings

2" and 3" Maxi Flange

We have expanded our product offering to include 2" and 3" maxi flange sanitary fittings and caps. The new sanitary fittings offer more options for the transfer of sensitive fluids and are still made to ASME-BPE specifications. They utilize our popular 600 Series barbs and can withstand -112° F (-80° C) temperatures to support your most demanding cryogenic applications.

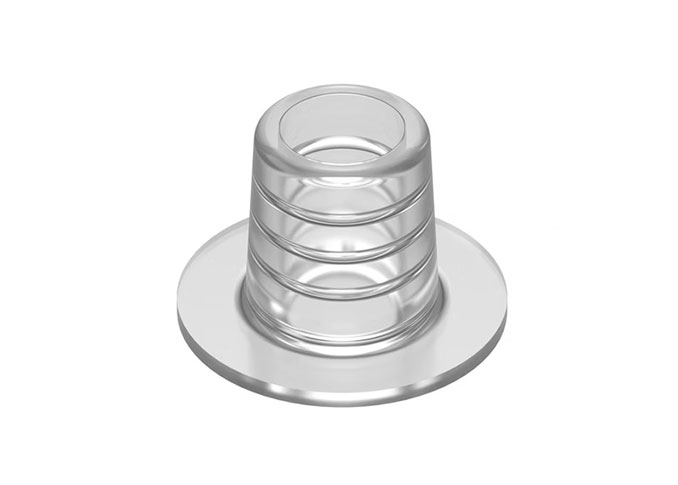

Medical Tubing Flanges

Heat-Sealable Connections

Our Halkey-Roberts line of medical tubing flanges offer reliable, heat-sealable connections for disposable systems, designed for compatibility with PVC or polyurethane films. Available in both 90° and straight configurations, these flanges support a variety of fluid management applications, including drainage and collection sets. The 90° flanges provide a right-angle connection ideal for compact setups, while the straight flanges feature an inner lip for secure tubing placement. Manufactured from clear, red, or black PVC or polyurethane, these components are well-suited for single-use medical devices.

167 series right angle tubing flange.

Features and Benefits

- Heat sealable to PVC or Polyurethane films

- Economical for disposable systems

Specifications and Technical Information

- Materials and available colors:

- PVC: clear

- Polyurethane/PVC: red or black

Additional Information

727 series right angle tubing flange.

Features and Benefits

- Heat sealable to PVC or Polyurethane films

- Economical for disposable systems

- Available colors: clear, red, black

Specifications and Technical Information

- Materials and available colors:

- PVC: clear

- Polyurethane/PVC: red or black

Additional Information

The 147 series straight tubing flanges are typically used to connect tubing to drainage or collection sets.

Features and Benefits

- Inner lip provides a positive stop to tubing or connection inserts

Specifications and Technical Information

- Materials and available colors:

- PVC: clear, red

- Polyurethane/PVC: red, black

Additional Information

The 47 series straight tubing flanges are typically used to connect tubing to drainage or collection sets.

Features and Benefits

- Inner lip provides a positive stop to tubing or connection inserts

- Low-cost flange

- Available in clear PVC

Specifications and Technical Information

- Materials:

- PVC

Additional Information

Industry-Leading Sanitary Flanges

Do more with your single-use bioprocesses and utilize Nordson MEDICAL's line of sanitary fittings.

- For use in single-use container fluid-transport systems and manifolds

- Animal-free materials

- No BSE documentation required

- Controlled surface finish and radiused flow surfaces allow smooth flow and prevent particulate build-up

- Interconnect with industry plastic and stainless steel parts

- Mini and Maxi sizes available

- Platinum-cured silicone gaskets available separately

Technical Information

| Materials | Polypropylene Natural Polyvinylidene Fluoride (PVDF) |

| Barb Sizes | 600 Series |

| Fits Tubing IDs | 1/4" (6.3 mm) 3/8" (9.5 mm) 1/2" (12.7 mm) 3/4" (19.0 mm) 1" (25.4 mm) |

| Flange Sizes | 3/4" (19.0 mm) - Mini 1-1/2" (38.1 mm) - Maxi 2" (50.8 mm) - Maxi 3" (76.2 mm) - Maxi Compatible with ASME-BPE Specifications |

| Sterilization | Autoclave EtO Compatible Gamma Radiation Stable X-Ray |

| Maximum Pressure | *3/4", 1-1/2", and 2" - 80 psi *3" - 50 psi |

| Tubing Types | Silicone C-Flex® Tygon® |

| Tubing Removal Force | 1/4" (6.3 mm) Polypropylene with C-Flex Shore A Tubing: 21 lb 1/2" (12.7 mm) Polypropylene with C-Flex Shore A Tubing: 89 lb 1" (24.4 mm) Polypropylene with C-Flex Shore A Tubing: 121 lb |

| Packaging | Individually Packaged |

*Sanitary fittings were tested pneumatically and hydrostatically.

Important: All HR Medical Components are shipped bulk, non-sterile, and are single patient use medical device components requiring further processing (e.g. assembly, packaging, sterilization) before clinical use. The buyer is responsible for determining effects of processing/multiple usage on these components, the appropriateness of the component in the final application, and pre/post sterilization shelf life.