Pressure-Relief Valves

Request a Quote »

Pressure-Relief Valves

Precision Pressure Management

We offer a comprehensive line of Halkey-Roberts pressure-relief valves designed to protect systems across medical, industrial, marine, and aerospace environments. Our portfolio includes one-way pressure and vacuum relief valves, dual-action breather valves, automatic and high-flow relief valves, push-open valves, and molded flanges for secure mounting. Each valve is engineered for consistent cracking and reseating performance, with individually calibrated components, corrosion-resistant materials, and a wide range of pressure settings to meet the demands of both low- and high-pressure applications.

One-Way Pressure and Vacuum Relief Valves

Consistent Operation

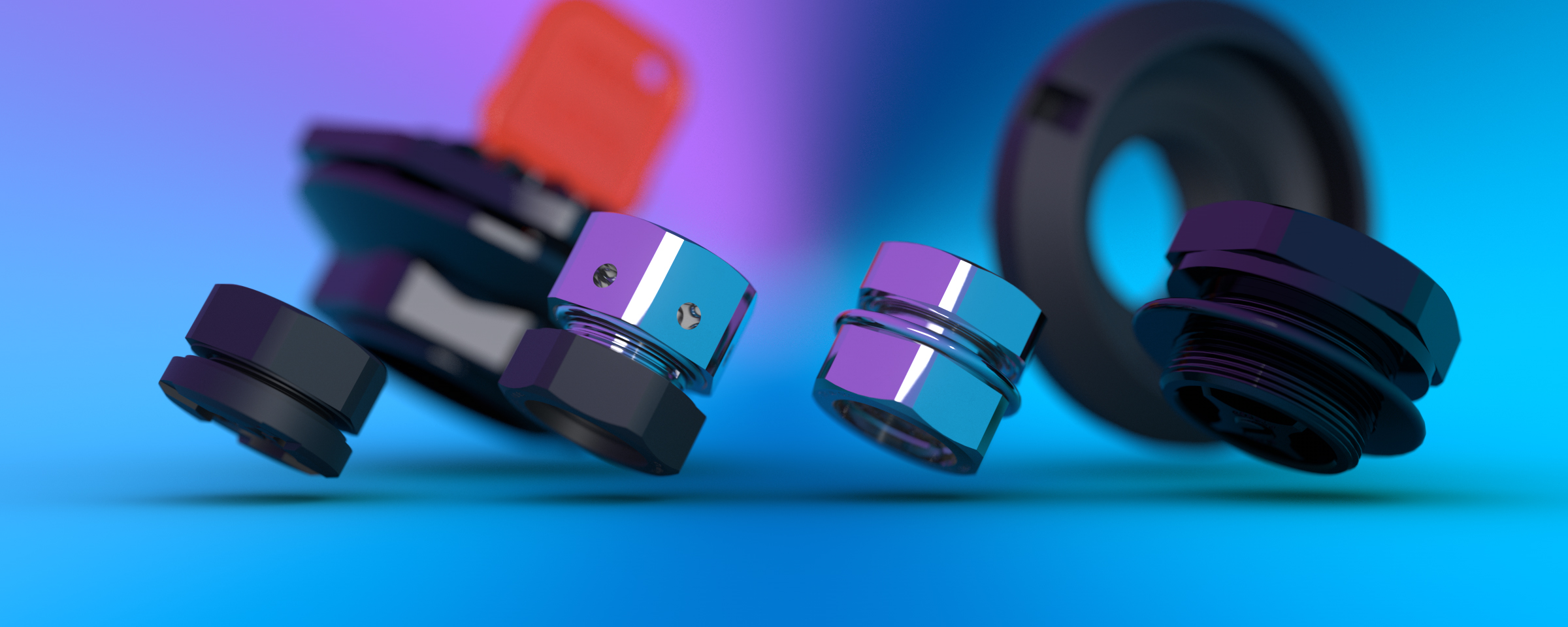

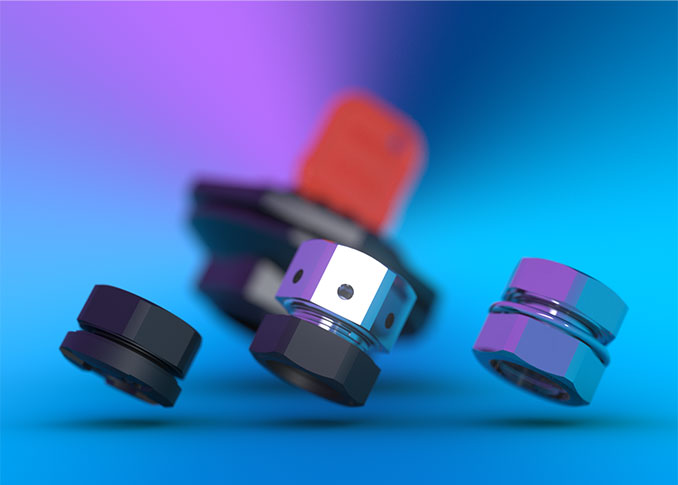

Our Halkey-Roberts line of one-way pressure and vacuum relief valves are precision-engineered for pressure control in critical applications such as medical devices, aircraft electronics, inflatable safety systems, and more. These compact, lightweight valves offer reliable cracking and reseating performance across a wide range of pressure differentials, with individually calibrated components and self-aligning poppets for consistent operation. Available in metal or plastic housings, with optional flanges and finishes, they are designed for easy integration into threaded or clamped installations.

The 750RP pressure relief and 750RV vacuum relief valves are designed for high-precision applications requiring exact automatic pressure or vacuum relief over a wide range of pressure differentials. These valves are used in a variety of applications including medical and surgical equipment, aircraft electronics, and other applications. The valves may be clamped in a 9/16" (14.3 mm) UN-2B threaded hole where the minimum wall thickness in 1/16".

Features and Benefits

- Provide precision relief over a wide range of differentials

- Compact and lightweight: approximate weight 0.30 ounces (8.5 grams)

- Individually calibrated and tested

- Self-aligning poppet allows for repeatable cracking and reseating from -65°F to 180°F (-54°C to 82°C)

- Available finishes: clear anodized or black anodized, EMI/RFI coating available

Specifications and Technical Information

- Materials:

- Body, stem and nut: Aluminum

- Retaining ring: Stainless steel

- Spring: Stainless steel

- Cracking pressure ±15% nominal. Reseat within 20% of nominal.

- Available spring pressures: 0.1 to 20.0 psi (other pressures available on request; minimum orders apply).

Additional Information

The 770 one-way pressure relief valve is designed for high-precision applications and is used in a variety of applications such as battery cases, radios, and aircraft computers. The 770RP model features special air slots to provide maximum airflow regardless of the internal configuration of the container. The 770 may be clamped in a 9/16" (14.3 mm) hole or screwed in a 9/16" UN-2B threaded hole where the minimum wall thickness is 1/16".

Features and Benefits

- Provides precision relief over a wide range of differentials

- Compact and lightweight: approximate weight 0.25 ounces (7 grams)

- Individually calibrated and tested

- Self-aligning poppet allows for repeatable cracking and reseating from -80°F to 180°F (-62°C to 82°C)

- Available finishes: Black anodized

Specifications and Technical Information

- Materials:

- Body, stem and nut: Aluminum

- Retaining ring: Stainless steel

- Spring: Stainless steel

- Cracking pressure ±15% nominal. Reseat within 20% of nominal.

- Available spring pressures: 0.1 to 20.0 psig (other pressures available on request; minimum orders apply).

Additional Information

The 780RPP pressure relief valve is used in a wide variety of inflatable products such as life rafts and boats, life vests, and safety evacuation slides.

Accessories

- 787RPPF neoprene flange fused for bonding to rubber coated fabrics

- 787SPFU urethane flange used for RF welding to a urethane coated fabric

- 780CTG cap assembly

Features and Benefits

- High-flow capabilities

- Provide precision relief over a wide range of differentials

- Compact and lightweight: approximate weight 0.6 ounces (17 grams)

- Available with or without flanges for mounting flexibility

- Individually calibrated and tested

- Precision self-aligning poppet allows for repeatable cracking and reseating

- Available colors: Black

Specifications and Technical Information

- Materials:

- Body, stem and nut: Aluminum

- Retaining ring: Stainless steel

- Spring: Stainless steel

- Cracking pressure ±15% nominal. Reseat within 20% of nominal.

- Available spring pressures: 0.1 to 15.0 psi (other pressures available on request; minimum orders apply).

Additional Information

The 780RPA pressure relief valve is used in a wide variety of inflatable products such as life rafts and boats, life vests, and safety evacuation slides.

Accessories

- 787RPF neoprene flange used for bonding to rubber coated fabric

- 787RPFU urethane flange used for RF welding to a urethane coated fabric

Features and Benefits

- High-flow capabilities

- Provide precision relief over a wide range of differentials

- Compact and lightweight: approximate weight 0.7 ounces (20 grams)

- Available with or without flanges for mounting flexibility

- Individually calibrated and tested

- Precision self-aligning poppet allows for repeatable cracking and reseating from -40°F to 180°F (-40°C to 82°C)

- Available in black

Specifications and Technical Information

- Materials:

- Body and nut: Aluminum

- Spring: Stainless steel

- Cracking pressure ±15% nominal. Reseat within 20% of nominal.

- Available spring pressures: 0.1 to 15.0 psi (other pressures available on request; minimum orders apply).

Additional Information

Dual-Action Breather Valves

Automatic Pressure and Vacuum Relief

Our dual-action breather valves are engineered for high-efficiency pressure and vacuum relief in rugged applications such as transport cases, military containers, and medical or industrial enclosures. These compact valves feature automatic bidirectional operation, corrosion-resistant materials, and a manual override for quick pressure release. Individually calibrated and tested, they deliver reliable performance across a wide range of environmental conditions. Standard pressure and vacuum settings range from 0.1 to 5.0 psig, depending on the model, with options available for both lower and higher flow requirements.

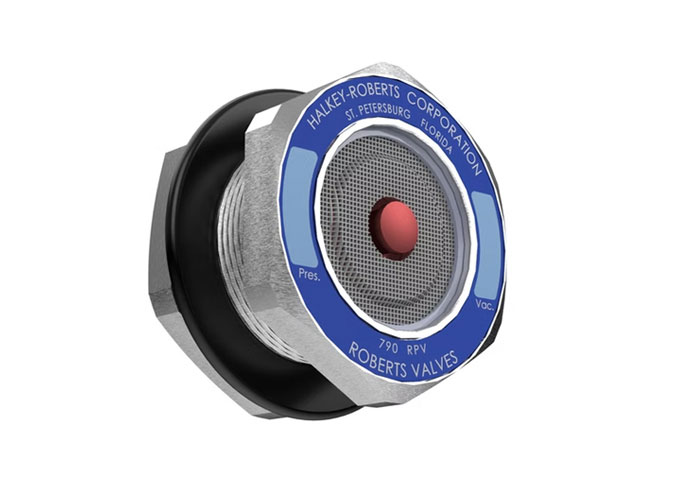

The 790 is an automatic dual-action valve designed to maximize the reliability of breather valves in critical conditions. The 790 is primarily used in the container industry, transportation cases and other military, industrial and medical applications. The 790 may be clamped in a 7/8" (22.2 mm) hole or screwed in a 7/8" (22.2 mm) 32 UN-2B threaded hole where the minimum wall thickness is 1/16" (1.62 mm) and a maximum of 5/16" (7.94 mm).

Features and Benefits

- High-efficiency, reliability, and flow in any position or hostile environment

- Manual override button for quick relief

- Corrosion-resistant materials

- Compact and lightweight: approximate weight 0.75 ounces (21 grams)

- Individually calibrated and tested

- Available coatings: clear anodized or black anodized standard; EMI/RFI coating available

Specifications and Technical Information

- Materials:

- Body, stem and nut: Aluminum

- Retaining ring: Stainless steel

- Spring: Stainless steel

- Cracking pressure ±15% nominal. Reseat within 20% of nominal.

- Standard pressure and vacuum settings: 0.1 to 5.0 psig (other pressures available on request; minimum orders apply).

Additional Information

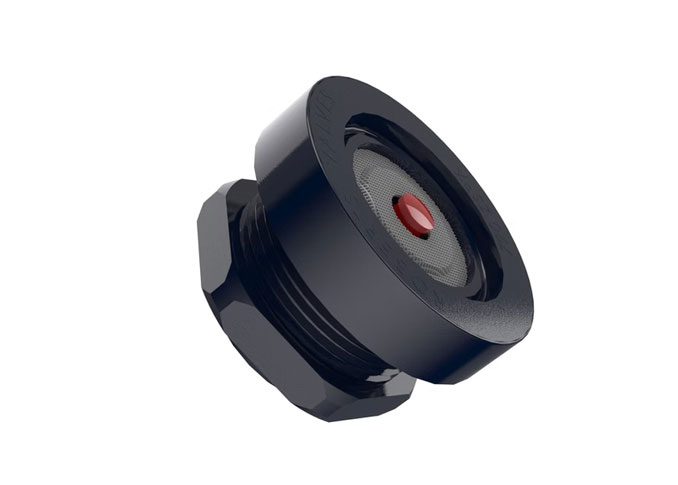

The 790ZSP is an automatic dual-action valve designed to maximize the reliability of breather valves in critical conditions. The 790ZSP is primarily used in the container industry, transportation cases and other military, industrial and medical applications. The 790ZSP may be clamped in a 1" (25.4 mm) hole or screwed in a 1" (25.4 mm) 20 UNEF-2B hole where the minimum wall thickness is 1/16" (1.62 mm) and a maximum of 5/16" (7.94 mm).

Features and Benefits

- High-efficiency, reliability, and flow in any position or hostile environment

- Manual override button for quick relief

- Compact and lightweight: approx. weight 1.15 ounces (33 grams)

- Individually calibrated and tested

- Corrosion-resistant materials

- Available coatings: black anodized aluminum standard; EMI/RFI coating available

Specifications and Technical Information

- Materials:

- Body, stem, nut, and clamp: Aluminum

- Retaining ring: Stainless steel

- Spring: Stainless steel

- Cracking pressure ±15% nominal. Reseat within 20% of nominal.

- Standard pressure and vacuum settings: 0.25 to 5.0 psig (other pressures available on request; minimum orders apply).

Additional Information

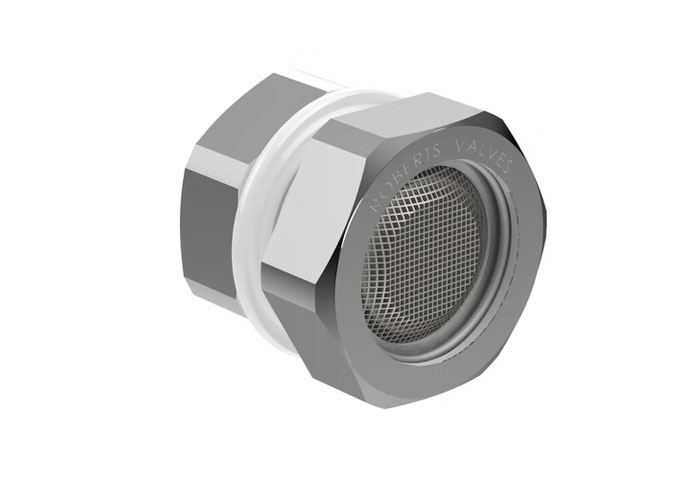

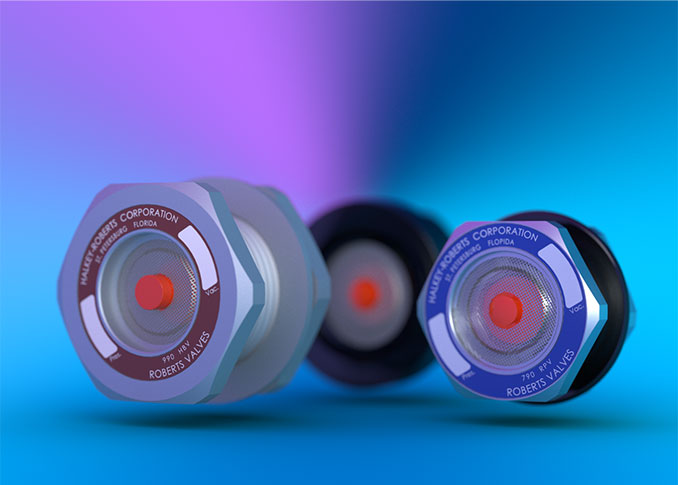

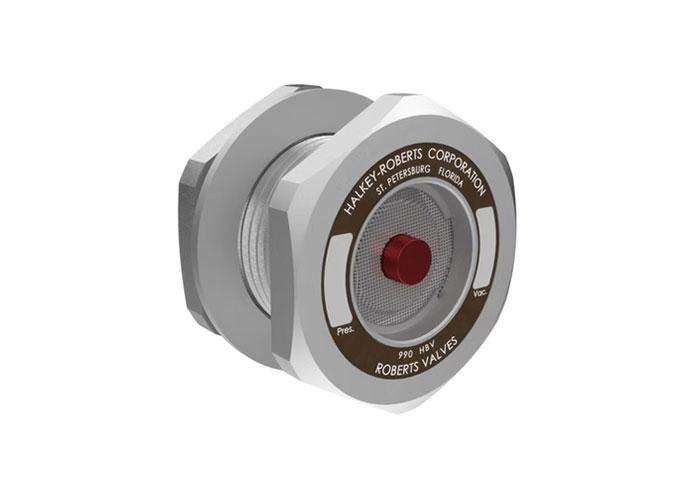

The 990 breather valve is primarily used in the container industry and for transportation cases and other military, industrial, and medical applications. The 990 is an automatic dual-action valve that utilizes the coaxial movement of pressure and vacuum poppets to maximize reliability, efficiency, and flow in any position or hostile environment. The 990 valve may be clamped in a 1.05" (26.7 mm) hole or screwed in a 1" (25.4 mm) 14 UN-2B straight pipe thread hole.

Features and Benefits

- Higher flow at lower pressure differentials

- Manual override button for quick relief

- Corrosion-resistant materials

- Compact and lightweight: approximate weight 1.5 ounces (43 grams)

- Individually calibrated and tested

- Self-aligning poppet allows for repeatable cracking and reseating

- Available coatings: Black anodized or clear anodized standard; EMI/RFI coating available

Specifications and Technical Information

- Materials:

- Body, stem, nut, clamp, and washer: Anodized aluminum

- Retaining ring: Stainless steel

- Spring: Stainless steel

- Cracking pressure ±15% nominal. Reseat within 20% of nominal.

- Standard pressure and vacuum settings: 0.1 to 3.0 psig (other settings available on request; minimum orders apply).

Additional Information

Automatic Relief Valves

Reliable Pressure Control for Inflatable Systems

Our automatic relief valves are designed to maintain safe pressure levels in inflatable boats, rafts, slides, barriers, and other inflatable structures. These screw-in valves offer high-flow performance with precise cracking and reseating, and each unit is individually tested and calibrated for accuracy. Available in white, with standard cracking pressures of 1.0, 2.0, 2.25, 3.25, and 4.0 psig, they provide dependable, maintenance-free pressure relief.

The 1080 automatic relief valve is a screw-in type relief valve designed for pressure relief applications in inflatable boats, rafts, slides, barriers, and other inflatable structures.

Features and Benefits

- High flow rate

- Precise cracking and reseat

- Each valve is individually tested and calibrated

- Available color in white

Specifications and Technical Information

- Materials:

- Body, cap, nut, screen: Acetal

- Stem: Aluminum

- Spring: Stainless steel

- Cracking pressures 1.0 psig, 2.0 psig, 2.25 psig, 3.25 psig, 4.0 psig

Additional Information

Molded Flanges

Adhesive-Free Mounting

Our molded flanges offer a low-profile, multipurpose solution for securely mounting valves in inflatable aviation and marine applications. Designed for use with high-flow relief valves, topping-off valves, inlet valves, and dual-action relief valves, these flanges clamp directly to a wide range of ductile materials—no adhesives or welding required. Made from durable glass-filled nylon, they meet ISO 15738 specifications.

This multipurpose flange can be used with the 984 high-flow pressure relief valve, topping off valve, inlet valve, and dual-action pressure relief valves.

Features and Benefits

- Unique clamp flange does not require adhesives or welding

- Clamps to a wide range of ductile materials used for aviation and marine rafts

- Low-profile design

Specifications and Technical Information

- Materials:

- Durable glass-filled nylon

- Meets specification to ISO 15738

Additional Information

High-Flow Relief Valves

Pressure Relief for Inflatable and High-Volume Systems

Our high-flow relief valves are engineered for demanding applications requiring rapid pressure release and consistent performance. One model features a large relief cap and anti-obstruction head, ideal for escape slides and inflatable boats, ensuring accurate crack settings and reliable operation even when packed. Another model offers aluminum-like strength with reduced weight, aerodynamic flow paths, and compliance with SOLAS life raft specifications. Both designs are individually calibrated and tested, with available spring pressures ranging from 0.05 to 7.0 psi, and custom settings available upon request.

The 984xx0022 hi-flo relief valve is designed for escape slides and other inflatable structures or boats.

Features and Benefits

- High flow

- Durability

- Large surface area of the relief cap allows for accurate crack settings

- Anti-obstruction head allows valve to be packed and to still open when inflated

Specifications and Technical Information

- Materials:

- Body: Aluminum

- Stem: Aluminum

- Spring: Stainless steel

- Available spring pressures (psi): 0.05, 0.1, 0.15, 0.5, 2.5, 3.0, 6.0 (other pressures available on request; minimum orders apply).

Additional Information

The 2110P hi-flo molded relief valves are designed for use in both commercial and recreational applications such as inflatable life rafts, large containers, and air bladders. Using unique molded shapes, engineered resins provide both aluminum-like strength and reduced weight. Aerodynamic poppet reduces high-pressure spots providing for a smooth and efficient flow path.

Features and Benefits

- Provide precision relief over a wide range of differentials

- Compact and lightweight: approximate weight 2.0 ounces (55 grams)

- Thread type: 1-1/2 - 16 - 2A

- Individually calibrated and tested

- Self-centering, articulated spring and poppet improve crack and reseat consistency from -40°F to 185°F (-40°C to 85°C)

- Meets all SOLAS life raft specifications for relief valves

Specifications and Technical Information

- Materials:

- Body, cap and flange: Glass-filled nylon

- Retainer, poppet and lock key: ABS

- Spring: Stainless steel

- O-ring: Buna-N

- Available spring pressures (psi): 0.3, 0.5, 1.0, 1.5, 3.0, 5.0, 7.0

Additional Information

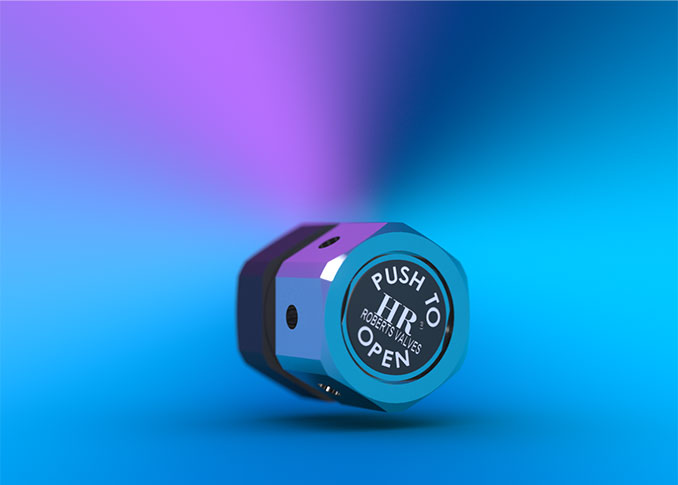

Push-Open Valves

Safe Pressure Equalization for Small Containers

Our push-open valves are designed to safely equalize pressure in small containers and cases before opening. With a compact, lightweight design, these valves release air or gas through radial holes when manually pressed, ensuring controlled venting. Easy to install through a single 9/16" hole, they feature an o-ring seal for airtight performance. Available in clear anodized or EMI/RFI-coated finishes, they operate reliably across a wide temperature range and meet DFARS and RoHS compliance standards.

The 750PU valve is designed to equalize the pressure in small containers and cases prior to opening. Simply push open to equalize pressure and direct the air or gas out the radial holes. The valve is easily installed through a single 9/16" (14.3mm) holed in the case or container. A nut tightens and squeezes an o-ring to insure an air tight seal.

Features and Benefits

- Provides safe air equalization

- Compact, lightweight: ~0.4 ounces (11.5 grams)

- Each valve 100% inspected prior to shipping

- Temperature range from -65°F to 180°F (-54°C to 82°C)

- Available finishes: Clear anodized or EMI/RIF coating

Specifications and Technical Information

- Materials:

- Body, stem and nut: Aluminum

- O-ring: Buna-N

- Outer O-ring: Neoprene

- Spring: Stainless steel

- DFARS and ROHS compliant

Additional Information

Protecting Sensitive Equipment

Our pressure-relief valves are used in harsh environments—from medical devices to military-grade enclosures.

- Precision-engineered for consistent cracking and reseating pressures

- Compact and lightweight designs ideal for space-constrained applications

- Individually calibrated and tested for quality assurance

- Wide operating temperature range: -65°F to 180°F (-54°C to 82°C)

- Corrosion-resistant materials including anodized aluminum and stainless steel

- Multiple configurations for pressure-only, vacuum-only, or dual-action relief

- Cracking pressures from 0.1 to 20.0 psi (others available upon request)

Technical Information

| Materials | Bodies, Stems, Nuts - Aluminum Springs - Stainless Steel |

| Colors | Clear Anodized Black Anodized |

| Configurations | One-Way Pressure One-Way Vacuum Dual-Action (Pressure & Vacuum) |

| Operating Temperature | -65°F to 180°F (-54°C to 82°C) |

| Operating Pressure | Up to 20 psi (Custom Ranges Available) |

| Cracking Pressure | 0.1 to 20.0 psi ±15% (Reseat Within 20% of Nominal) |

Important: All HR Medical Components are shipped bulk, non-sterile, and are single patient use medical device components requiring further processing (e.g. assembly, packaging, sterilization) before clinical use. The buyer is responsible for determining effects of processing/multiple usage on these components, the appropriateness of the component in the final application, and pre/post sterilization shelf life.