Medical Check Valves

Shop Now »

What is a Check Valve?

Components that Control Flow

A check valve is a component that regulates the directional flow of fluids and comes in diverse configurations tailored to specific needs. Single-configuration check valves prevent backflow in one direction, requiring a positive pressure differential for fluid passage. They feature terminations such as luers, bond sockets, bond posts, and barbed designs. Double-configuration check valves manage bidirectional flow by directing fluid to multiple outlets sequentially. Our check valves are engineered with a range of opening pressure ratings, from low pressure options to high pressure variants, like anti-siphon valves, that resist gravity-induced flow. Made with USP Class VI compliant materials, our medical-grade check valves prioritize safety and compatibility with the human body. They minimize contamination risks while facilitating seamless priming and accommodating higher flow rates. Ideal for infusion, drainage, and irrigation applications, our check valves are essential for medical device designers seeking reliability and performance.

Material Information

We offer our customers direct technical information from resin manufacturers regarding the resins we utilize. This includes material data such as regulatory compliance, MSDS, typical properties, sterilization stability, and chemical resistance. We encourage testing our products in your specific application to ensure they meet your requirements effectively.

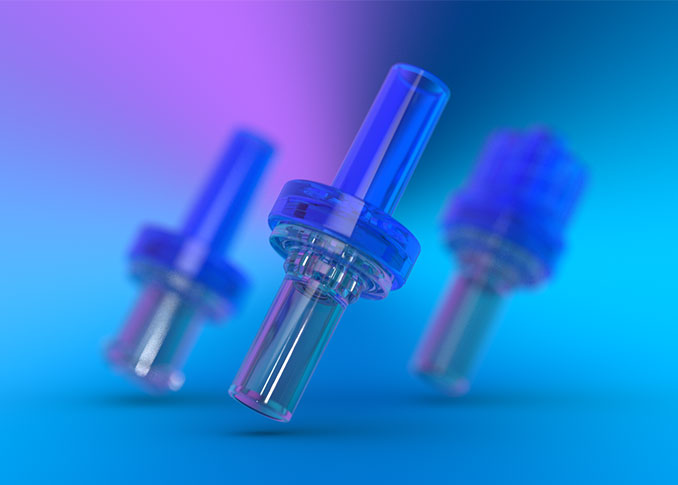

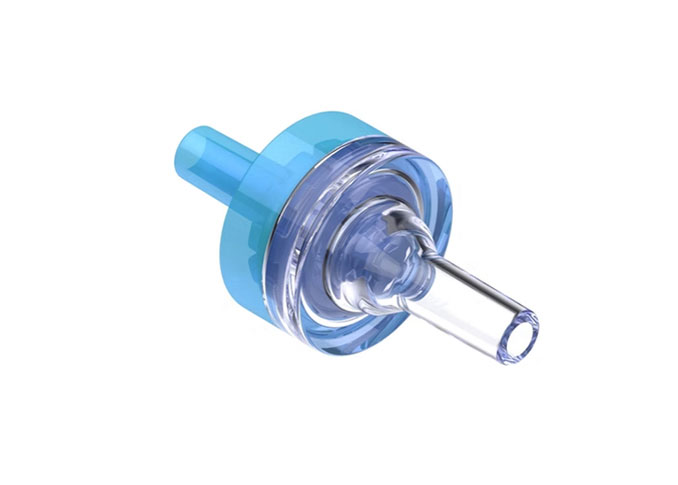

Single-Configuration Check Valves

Plastic Valves to Prevent Contamination

Our single-configuration check valves offer a versatile range of anti-siphon and barbed configurations crafted from a variety of high-quality materials. We also offer gravity set check valves as part of this range. Our single check valves are available with terminations such as male and female locking luers, bond sockets, and bond posts in various sizes and combinations. Designed to minimize contamination risks, these valves boast precise, low opening pressures and superior flow rates, making them indispensable for medical device designers. Each valve includes DEHP- and latex-free silicone diaphragms, ensuring low priming volume and ease of air bubble removal during operation in any orientation.

Single-Configuration Valves for Accurate Flow Control

Nordson MEDICAL's anti-siphon check valves excel in controlling directional flow and preventing backflow, featuring higher opening pressures that effectively safeguard against inadvertent fluid flow, particularly when connecting to higher-flow lines. Crafted from medical-grade materials, these valves are meticulously engineered to operate flawlessly in any orientation, offering improved air vent functionality crucial for healthcare applications like enteral feeding. Meeting rigorous USP Class VI and ISO 10993 standards, our anti-siphon check valves are trusted worldwide by healthcare professionals for their superior quality and reliability.

Single-Configuration Valves with High Flow Rates

Our high-flow check valves are specifically designed using premium medical-grade materials certified to meet USP Class VI and ISO 10993 standards, ensuring optimal performance for flushing and irrigating body cavities. Engineered to maximize flow efficiency with a less restrictive path, these valves offer enhanced responsiveness and facilitate efficient removal of air bubbles during priming.

Single-Configuration Valves for IV Gravity Sets

We offer check valves specifically designed for gravity sets, crafted from medical-grade materials and engineered to effectively prevent backflow in their closed-valve state. These unidirectional valves stand out with the lowest cracking pressure available, ensuring reliable operation in any spatial orientation. Enhanced with improved air vent functionality for critical applications like IV administration, our gravity set check valves are indispensable in medical settings where eliminating backflow is paramount.

Single-Configuration Valves with Secure Connections

Our barbed check valves are available with 3/32" (2.4 mm) and 1/8" (3.2 mm) single barb ends, offered in barb-to-barb straight-through, reducing, and barb-to-male/female luer configurations. Designed to minimize contamination risks, these valves boast precise, low cracking pressures and higher flow rates, making them ideal for medical device designers focused on infusion, drainage, and irrigation applications.

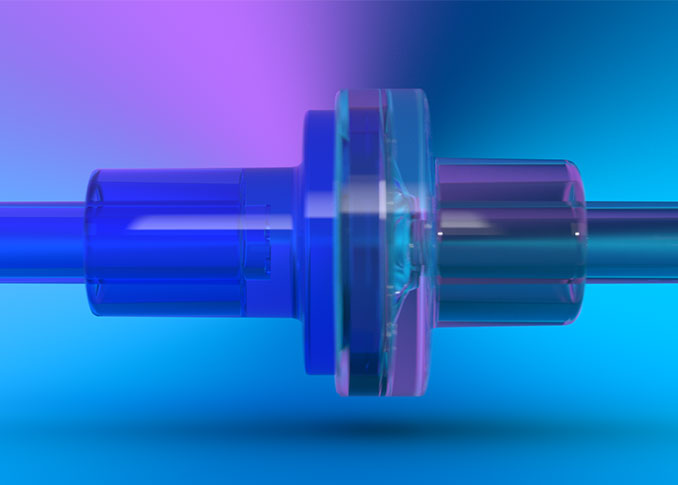

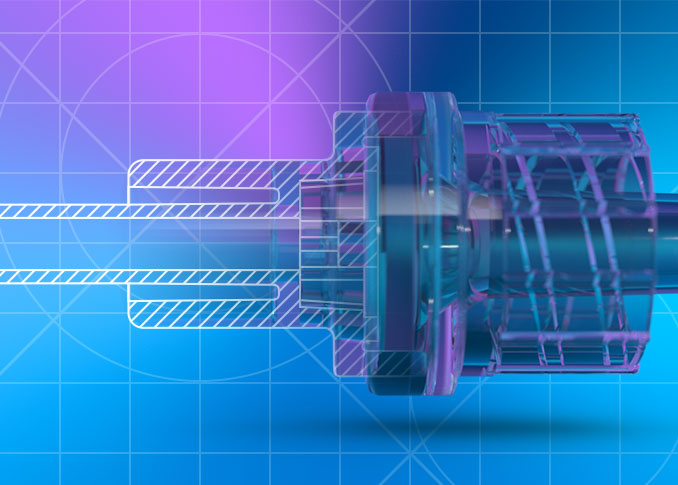

Double-Configuration Check Valves

Plastic Valves to Maintain Fluid Purity

Nordson MEDICAL's unique bi-directional double check valves, are expertly designed to transfer clean fluid from a supply vessel to a use site without contamination. The fluid supply vessel connects to the valve supply port (chimney) via a luer connection or tubing. Fluid is withdrawn from the supply vessel by a syringe or another device attached to the aspiration port. When the syringe is compressed, the fluid is transferred through the exit port to the use site, maintaining its purity. These double check valves are crafted from medical-grade polycarbonate resin with a silicone diaphragm. Featuring two inlet ports, these check valves seamlessly connect to female luer aspiration and male luer discharge ports. Our valves ensure reliable, contamination-free fluid transfer without disconnecting the syringe, making them an ideal choice for medical applications.

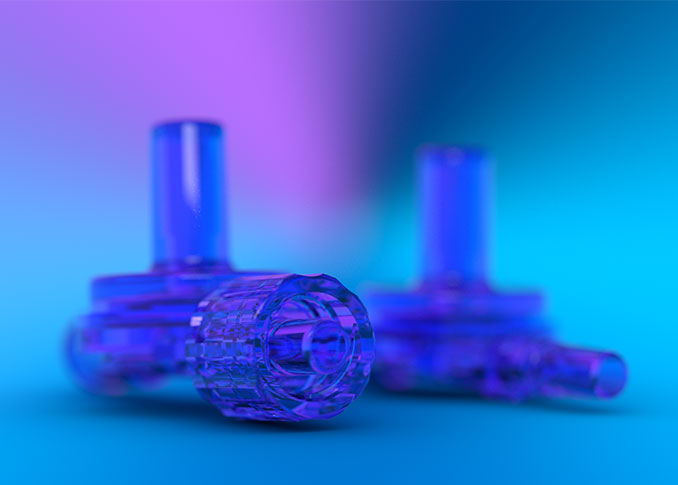

Luer-Activated Valves

Providing Closed Systems

Our Halkey-Roberts line of luer-activated valves provides needle-free access solutions designed for secure, closed-system fluid control in disposable medical applications. These valves are activated by standard luer syringes and connectors, offering reliable performance in flushing, fluid delivery, and catheter-related procedures. The product line includes a variety of body profiles, connection types (including luer-lock activated options), and several color choices to meet diverse clinical and manufacturing needs. All valves are economically priced, compatible with standard luer interfaces, and constructed from medical-grade materials for safety and durability.

This needlefree, luer-activated check valve with a female luer lock provides a safe and efficient closed-system access point for fluid delivery. Designed for compatibility with all standard luer syringes, it offers a cost-effective solution for disposable medical applications, helping to reduce contamination risks and improve workflow safety.

Features and Benefits

- Economical needlefree access site

- Valve stem and body mate securely with all standard luer syringes

- Luer lock ears for positive securement

Specifications and Technical Information

- Materials and available colors:

- Body: PVC, Polycarbonate, ABS, or Polypropylene

- Stem: Silicone

- Plug: Polypropylene

Additional Information

This needlefree, luer-activated check valve features a dual configuration with female and male luer locks, offering a secure, closed-system access point for fluid control. Designed for compatibility with all standard luer syringes, it provides a cost-effective and reliable solution for disposable medical applications, helping to reduce contamination risks and improve safety.

Features and Benefits

- Economical needlefree access site

- Valve stem and body mate securely with all standard luer syringes

Specifications and Technical Information

- Materials and available colors:

- Body and adapter: PVC or PC

- Stem: Silicone

- Plug: Polypropylene

Additional Information

This needlefree, male luer-activated bondable check valve provides a secure, closed-system access point for fluid control, compatible with all standard luer syringes. Ideal for disposable applications, it offers a cost-effective solution that enhances safety and maintains system integrity.

Features and Benefits

- Economical needlefree access site

- Valve stem and body mate securely with all standard luer syringes

Specifications and Technical Information

- Materials and available colors:

- Body: PVC

- Male luer adapter: PVC

- Stem: Silicone

- Plug: Polypropylene

Additional Information

This compact, needlefree luer-activated check valve features a short body design with a female luer lock for secure, closed-system access. Engineered for compatibility with all standard luer syringes, it offers a space-saving, economical solution for disposable medical applications where reliability and safety are essential.

Features and Benefits

- Economical needlefree access site

- Valve stem and body mate securely with all standard luer syringes

Specifications and Technical Information

- Materials and available colors:

- Body: PVC or Polycarbonate

- Stem: Silicone

- Spring: Stainless steel

- Plug: Polypropylene

Additional Information

This medium body, needlefree luer-activated check valve with a female luer lock provides a secure, closed-system access point for fluid transfer in medical applications. Designed for compatibility with all standard luer syringes, it offers a reliable and economical solution for disposable systems where safety and performance are critical.

Features and Benefits

- Economical needlefree access site

- Valve stem and body mate securely with all standard luer syringes

Specifications and Technical Information

- Materials and available colors:

- Body: Polycarbonate

- Stem: Silicone

- Spring: Stainless steel

- Plug: HDPE

Additional Information

This is a three-piece, luer-activated valve available in multiple colors, designed for disposable use with secure syringe compatibility and reliable fluid control.

Features and Benefits

- Valve stem and body mate securely with all standard luer syringes

- Economically priced for disposable applications

Specifications and Technical Information

- Materials and available colors:

- Body: Polypropylene

- Stem: Silicone

- Colors: Clear, white, green

Additional Information

This is a three-piece valve engineered to fill, hold, and release controlled amounts of fluid or gas on demand. Designed for precision and reliability, it’s ideal for disposable medical applications requiring secure and repeatable flow control.

Features and Benefits

- Valve stem and body mate securely with all standard luer syringes

- Economically priced for disposable applications

Specifications and Technical Information

- Materials and available colors:

- Body: Polycarbonate, PVC, Polypropylene, or ABS

- Stem: Silicone

- Stem: Silicone

- Colors: Clear, white, clear with green liner

Additional Information

V24500 is a medium profile, two-piece luer-activated check valve designed for secure integration into catheter tubing systems. Featuring a sleeve molded directly to the valve body, it enables a one-step crimp attachment for streamlined assembly. This valve offers reliable performance and compatibility with all standard luer syringes, making it an ideal choice for disposable medical applications.

Features and Benefits

- Valve stem and body mate securely with all standard luer syringes

- Economically priced for disposable applications

Specifications and Technical Information

- Materials and available colors:

- Body: ABS

- Stem: Silicone

- Colors: White, blue, green, purple, red, yellow, orange

Additional Information

2470630 is a short body luer-activated check valve featuring an internal spring mechanism for responsive, one-way fluid control. Its compact design and female luer connector make it ideal for space-constrained medical applications. Compatible with all standard luer syringes, this valve offers dependable performance in disposable systems.

Features and Benefits

- Valve stem and body mate securely with all standard luer syringes

- Low-profile

Specifications and Technical Information

- Materials and available colors:

- Body: PVC or Polycarbonate

- Stem: Silicone

- Spring: Stainless steel

Additional Information

This low-profile valve is specifically designed for inflating and deflating catheter balloons, offering high flow performance in a compact form factor. Ideal for gastric feeding applications, it ensures fast and efficient fluid transfer while maintaining a secure connection. Available with color-coded stems for easy identification, this valve supports streamlined clinical workflows and reliable operation.

Features and Benefits

- Very low profile

- Ideal for gastric feeding catheters

- High-flow for fast inflate/deflate

Specifications and Technical Information

- Materials and available colors:

- Body: Polycarbonate

- Stem: Silicone

- Spring: Stainless steel

- Colors: Green Stem, Blue Stem

Additional Information

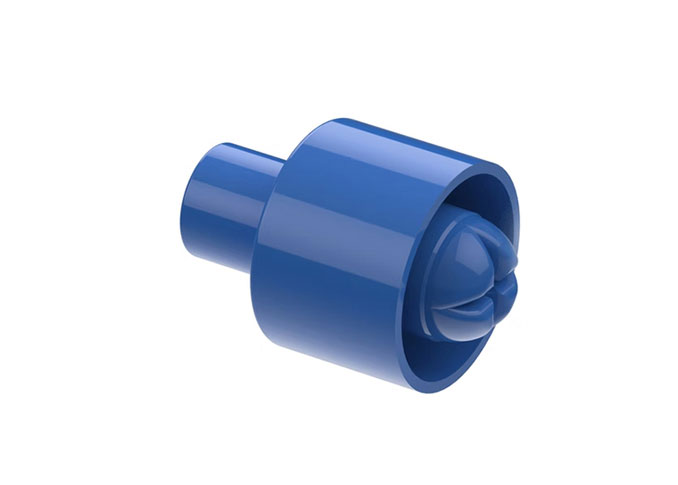

One-Way Check Valves

Unidirectional Flow

Our Halkey-Roberts line of one-way check valves is designed to ensure unidirectional flow and prevent backflow in a variety of fluid delivery applications. Dome valves offer low opening pressure and high backpressure resistance, making them ideal for IV fluid systems. Disc valves deliver high-flow performance across a wide pressure range. Both valves are constructed with durable polycarbonate housings and silicone seals, providing reliable, closed-system fluid control in medical and healthcare environments.

241410324 is a normally closed, one-way check valve engineered to prevent backflow in a wide range of IV fluid delivery applications. Its compact design and reliable performance make it ideal for disposable medical systems requiring consistent, directional flow control. With low opening pressure and high backpressure resistance, it ensures safe and efficient fluid management.

Features and Benefits

- Designed to prevent backflow during a wide variety of fluid delivery applications

- Low opening pressue: 0.43 psi (0.03 bar)

- Backpressure resistance >45 psi (3.1 bar)

Specifications and Technical Information

- Materials and available colors:

- Housing: Polycarbonate

- Dome Seal: Silicone

Additional Information

This one-way check valve is designed for dependable performance across a wide range of fluid delivery applications. Its streamlined construction supports high flow rates while maintaining directional control, making it ideal for use in disposable medical systems where consistent, one-way flow is essential.

Features and Benefits

- High flow rate across a wide range of pressures

Specifications and Technical Information

- Materials and available colors:

- Housing: Polycarbonate

- Disc Seal: Silicone

Additional Information

Pressure-Relief Valves

Protecting Medical Systems

The Halkey-Roberts line of pressure-relief valves is engineered to protect medical devices and systems from over-pressurization by automatically releasing excess pressure in fluid or gas circuits. These valves are ideal for applications such as balloon catheter inflation, pump circuits, and sensitive equipment protection. Available in a variety of configurations—including luer lock, T-port, and pressure-activated designs—each valve features customizable spring settings to meet specific pressure thresholds. Constructed from medical-grade materials, these valves offer reliable, in-line performance and are suitable for both disposable and reusable systems.

These relief valves are designed for in-line pressure relief in fluid and gas applications. Featuring convenient female and male luer lock connections, these valves are easy to integrate into medical systems such as balloon catheters and pump circuits. With customizable spring options ranging from 2.5 psi to 100 psi, they provide reliable protection against over-pressurization and help safeguard sensitive equipment.

Features and Benefits

- Convenient connection via female and male luer locks

- Customizable springs for pressures from 2.5 psi to 100 psi

- Easily connected in-line to prevent over pressurization of balloon catheters, pump circuits, and can help to protect sensitive equipment

- Applications for fluid and gas

- Designed to be connected in-line via luer lock connections

Specifications and Technical Information

- Materials and available colors:

- Body: Polycarbonate

- Stem: Silicone

- Spring: Stainless steel

- Plug: Polypropylene

- Male Spin Lock: Polycarbonate

Additional Information

These relief valves are designed for in-line pressure relief in medical and fluid management systems. These compact valves can be bonded directly into tubing assemblies, offering a flexible and secure solution for protecting devices from over-pressurization. With customizable spring options ranging from 2.5 psi to 80 psi, they provide precise pressure control across a variety of applications.

Features and Benefits

- Customizable springs for pressures from 2.5 psi to 80 psi

- Can be bonded in-line

- Designed for 0.160" (4 mm) OD tubing

Specifications and Technical Information

- Materials and available colors:

- Body: Polycarbonate

- Stem: Silicone

- Spring: Stainless steel

- Plug: Polypropylene

Additional Information

These valves automatically hold and release controlled amounts of fluid or gas. With spring options ranging from 0.5 psi to 7.4 psi, they provide a low-cost, compact solution for pressure relief in medical applications.

Features and Benefits

- Customized springs for pressures from 0.5 psi to 7.4 psi

- Low-cost alternative for pressure relief

Specifications and Technical Information

- Materials and available colors:

- Housing: Medical-grade acrylic

- Valve: Silicone

- Spring: Stainless steel

Additional Information

Bleed Valves

One-Way Pressure Release

Our Halkey-Roberts line of bleed valves with one-way check valves features compact, reliable components designed for controlled venting and backflow prevention in fluid and air systems. Available in configurations for female luer fittings, 1/4" (6.35 mm) tubing, and 1/8" (3.175 mm) tubing, these valves support a wide range of applications, including inflatable systems and secure luer connections. Each valve ensures safe, one-way pressure release, enhancing system performance and user safety. Constructed with a polypropylene body and ABS cap, they are available in black or white for easy integration into various setups.

This one-way bleed valve is designed for use with female luer connections, allowing controlled air release in inflatable medical systems. Its compact, low-profile design supports precise pressure management.

Features and Benefits

- Female luer compatibility

Specifications and Technical Information

- Materials and available colors:

- Body: Polypropylene

- Cap: ABS

- Colors: Black

Additional Information

This one-way bleed valve is designed to fit 1/4" ID tubing and provides controlled air release for precise pressure regulation in inflatable systems. Its compact, in-line design makes it ideal for applications requiring reliable venting without compromising system integrity.

Features and Benefits

- Female luer compatibility

Specifications and Technical Information

- Materials and available colors:

- Body: Polypropylene

- Cap: ABS

- Colors: Black

Additional Information

This one-way bleed valve is designed for use with 0.125" (3.175 mm) ID tubing, providing controlled air release in inflatable systems. Compact and efficient, it is ideal for applications requiring precise pressure control and directional airflow, such as inflatable medical devices and air management systems.

Features and Benefits

- Ideal for one-way check valves

- Hold and release air from inflatable bags

Specifications and Technical Information

- Materials and available colors:

- Body: Polypropylene

- Cap: ABS

- Colors: Black or white

Additional Information

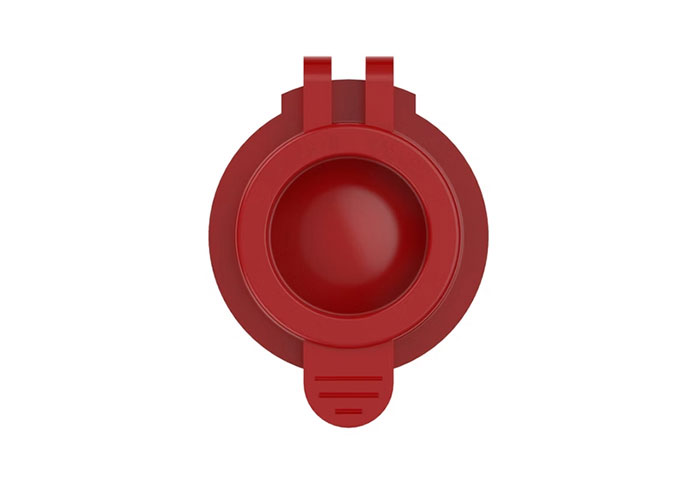

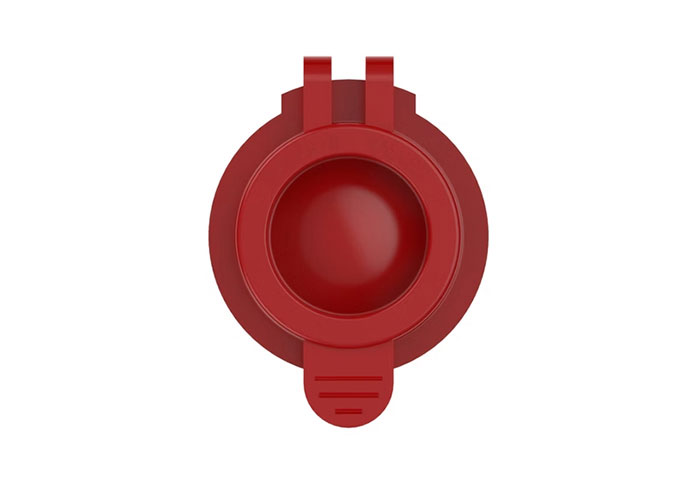

Fill/Drain Ports

Medical Closures with Check Valves

Our medical-grade fill and drain ports are designed to provide safe, efficient fluid management for disposable medical bags. These closures feature integrated one-way check valves or flapper mechanisms to prevent backflow and ensure controlled filling and emptying. With options for both standard and high-capacity applications, they support a wide range of clinical needs. Made from USP Class VI PVC, including DEHP-free materials, they are available in clear for visibility or in a variety of colors to suit specific requirements.

The 650 series fill/drain port is engineered for efficiency and safety in medical fluid disposal. This secure closure is designed to integrate seamlessly with disposable medical bags. Ideal for fluid management applications, it ensures reliable containment and rapid drainage, helping healthcare professionals maintain a clean and controlled environment.

Features and Benefits

- Secure closure to prevent leaks

- Rapid drainage

- Designed to fit standard disposable medical bags

Specifications and Technical Information

- Materials and available colors:

- Medical-grade USP Class VI PVC

- DEHP-free material available

- Colors: Red (other colors available by special order; minimum quantities apply)

Additional Information

This fill/drain port offers a durable and efficient solution for fluid transfer in medical bag systems. Featuring an integrated flapper-style check valve, it provides dependable reverse flow protection, ensuring safe and hygienic fluid management in critical care environments.

Features and Benefits

- Automatic reverse flow checking with a flapper

- Large dumping capacity

Specifications and Technical Information

- Materials and available colors:

- Medical-grade USP Class VI PVC

- PVC

- Colors: Clear or red

Additional Information

Custom-Configuration Check Valves

Medical Valves Designed to Meet Your Needs

Nordson MEDICAL is your single-source partner for custom-configuration check valves, offering seamless collaboration from initial concept through production scale-up. We tailor our check valves to meet your specific requirements, from customized connecting geometry to precise valve performance characteristics, ensuring they excel in the most demanding applications. Contact our customer service team at 970-267-5200 today to discover how partnering with Nordson MEDICAL delivers world-class precision. By working closely with you to design and develop check valves that meet your dimensional and performance specifications, we provide unparalleled manufacturing capabilities and regulatory support, essential for the success of your product.

Plastic Check Valves

Trust our medical valves to accurately control flow and reduce the risk of contamination in your medical applications.

- Designed to prevent backflow

- Biopharma-grade materials meet USP Class VI and ISO 10993 criteria

- Clean room manufactured

- Air entrapment easily alleviated during priming

- Operation in any spatial orientation to prevent unwanted free flow under gravity

- Normally closed valve for optimum flow control

- Lowest cracking pressures on the market

- Improves air vent functionality for applications such as enteral feeding

- High-flow options for flushing and irrigation applications

- Barbs that work with tube clamps

- Bi-directional double check valve options for clean fluid transfer from supply to site

- Double check valves with a female luer aspiration port and a male luer discharge port

Technical Information

| Materials | Housing - MABS, SAN, Polycarbonate, Polypropylene, PVC Diaphragm - Silicone (Phthalate-Free and Latex-Free), Platinum-Cured Silicone Spring: Stainless Steel Plug: HDPE, Polypropylene |

| Configurations | Barb to Barb Straight Through Reducing Barb to Male/Female Luer Luer-Activated Needlefree Pressure-Activated Crimp-On Short Body Low Profile |

| Barb Sizes | Single Barb Ends - 3/32" (2.4 mm), 1/8" (3.2 mm) 600 Series - 1/4" (6.4 mm) |

| Fits Tubing ODs | High-Flow Check Valves - 8.8 mm |

| Sterilization | EtO Compatible Gamma Radiation Stable |

| Flow Rate | Anti-Siphon Check Valves - 110 ml/min - 200 ml/min High-Flow Check Valves - ≥ 1000 ml/min with Water at a Pressure of 100 mb High Flow Check Valves - ≥ 3000 ml/min with Water at a Pressure of 1 bar Gravity Set Check Valves - 90 ml/min - 150 ml/min Barbed Check Valves - ≥ 150 ml/min |

| Cracking Pressure | Anti-Siphon Check Valves - 1.450 psig (100 mb) - 4.351 psig (300 mb) High-Flow Check Valves - ≤ .290 psig (20 mb) Gravity Set Check Valves - ≤ .174 psig (12 mb) Barbed Check Valves - ≤ .087 psig (6 mb) |

| Maximum Back Pressure | Anti-Siphon Check Valves - 73.000 psig (5 bar) - 304.500 psig (21 bar) High-Flow Check Valves - 14.500 psig (1 bar) Gravity Set Check Valves - 73.000 psig (5 bar) - 116.030 psig (8 bar) Barbed Check Valves - 73.000 psig (5 bar) Double Check Valves - 2 psi (0.14 bar) - 5 psi (0.34 bar) |

Important: All HR Medical Components are shipped bulk, non-sterile, and are single patient use medical device components requiring further processing (e.g. assembly, packaging, sterilization) before clinical use. The buyer is responsible for determining effects of processing/multiple usage on these components, the appropriateness of the component in the final application, and pre/post sterilization shelf life.

Custom Components

Whether it's a slight modification of one of our catalog components, a design that you need manufactured, or something completely unique that requires full product development, Nordson MEDICAL has the experience and proficiency to support your project from concept through full-scale manufacturing.