Build-a-Part® Fittings

Shop Now »

Bondable Prototyping Fittings

Interchangeable Components

Build-a-Part® bondable prototype fittings allow you to choose interchangeable components to create a tubing set prototype for evaluation before committing to production. You can connect junction blocks to luer, hose barb, or threaded components to create multiport, multiaxis products that receive and redirect flow in your desired direction.

Bonding Suggestions

How to Apply Solvents

Prior to actually bonding, press together a model of the manifold to use as a reference. Do not mix plastic resins. Consult your adhesive specialist if you need to bond dissimilar materials.

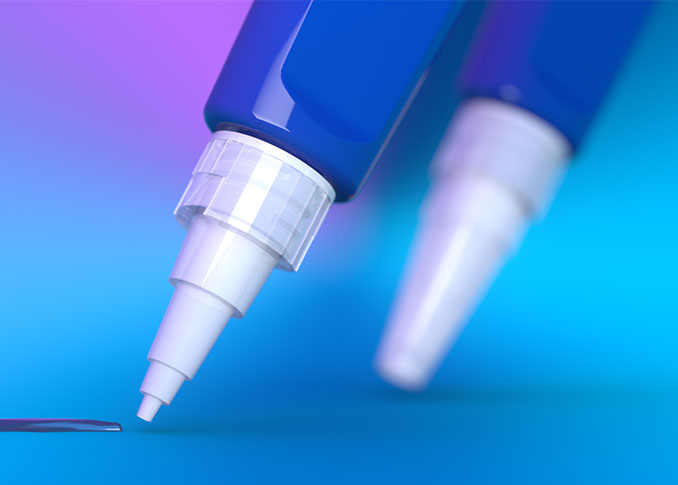

These components are designed for bonding with any one of a number of solvents, but other adhesive systems may be used. When solvent bonding, use a very small gauge needle (typically 27 or 30) for best solvent control. Consult your adhesive specialist for guidance on other systems.

Apply solvent sparingly. Most solvents are low viscosity and readily wick into the bondline. Excessive solvent may compromise the aesthetics and the function of the assembly.

Press the mating components together leaving a .01 - .03" gap between them for the solvent. Place the components in an orientation such that they may be rotated 1/4 turn to their final position after applying the solvent. After applying solvent, wait a few seconds, then rotate the components to their final position. When making a long manifold with bondable junction blocks it may be helpful to push the assembly against a flat surface to align the blocks before the solvent has set.

Design Your New Component

You no longer need to be constrained by the limitations of injection molding tool design. The exact fitting, in the optimal layout for your process or product concept, is right at your fingertips.

Technical Information

| Materials | ABS Polysulfone |

| Configurations | Straight Elbow Tee |

| Thread Styles (Male) | 10-32 UNF 1/16-27 NPT 1/8-27 NPT 1/4-28 UNF M6x1 |

| Fits Tubing IDs | 1/16" (1.6 mm) 3/32" (2.4 mm) 1/8" (3.2 mm) |

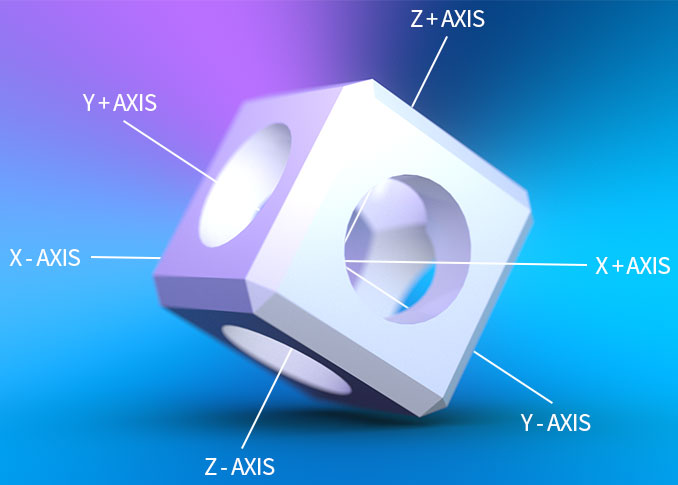

Junction Block Configurations

| Block | X+ Axis | X- Axis | Y+ Axis | Y- Axis | Z+ Axis | Z- Axis |

|---|---|---|---|---|---|---|

| BDJ05 | Female | — | Female | — | Female | — |

| BDJ06 | Female | — | Female | — | Female | Female |

| BDJ07 | Female | Female | Female | Female | Female | — |

| BDJ08 | Female | Female | Female | Female | Female | Female |

| BDJ09 | Male | Female | Female | — | Female | Female |

| BDJ10 | Male | Female | Female | Female | Female | Female |

| BDJ11 | Male | Female | Female | Female | — | — |

| BDJ13 | Male | Female | Female | — | Female | — |

| BDJ14 | Male | Female | — | — | — | — |

| BDJ15 | Female | Female | — | — | — | — |

| BDJ16 | Female | Female | — | Female* | — | — |

| BDJ17 | Male | Female | Female* | — | — | — |

| BDJ18 | Male** | Female | Female | — | Female | Female |

| BDJ19 | Male** | Female | Female | Female | Female | Female |

| BDJ20 | Male** | Female | Female | Female | — | — |

| BDJ21 | Male** | Female | Female | — | — | — |

| BDJ22 | Male** | Female | Female | — | Female | — |

Note: *For non-flow manifolding; **For use with BDMD

Custom Components

Whether it's a slight modification of one of our catalog components, a design that you need manufactured, or something completely unique that requires full product development, Nordson MEDICAL has the experience and proficiency to support your project from concept through full-scale manufacturing.